Helpful Information

Frequently Asked Questions ~Metalworking Lubricants for Presses~

In this blog post, we will use a Q&A format to discuss frequently asked questions about metalworking lubricants. We also recommend this section for new learners! Q1: What are press metalworking...

Should I Choose a Straightener Feeder or a Loop Pit Line? ~Productivity and Installation Conditions~

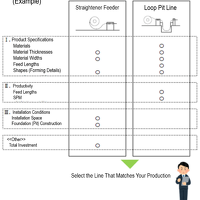

Hello! This blog post continues our discussion of the subject "Should I Choose a Straightener Feeder or a Loop Pit Line?" In our previous blog post we explained (1) Product Specifications (i.e., wh...

Should I Choose a Straightener Feeder or a Loop Pit Line? ~Product Specifications~

Hello! In this blog post about whether to select a straightener feeder or a loop pit line, we will be comparing the three selection elements of '(1) Product Specifications,' '(2) Productivity,' and...

Should I Choose a Straightener Feeder or a Loop Pit Line? ~The Basics~

Hello! In this blog post we will compare the various characteristics of straightener feeder lines and loop pit-type coil lines when it comes to choosing between the two types. In the blog entry bel...

What Spare Parts Should We Keep on Hand?

Have you ever had a press stop running and, as you are frantically looking for a replacement part, you are shocked to learn that it has a very long lead time? Here's some advice to avoid such a pre...

IS5_7967.jpg)

Press Vibration Isolator Types and Selection Criteria

Press vibration isolators are used to combat vibration pollution and to protect the work environment from machine vibration that occurs while forming products, thereby preventing adverse effects on...

What is the Total Press Weight? Understanding the Total Press Weight Applied on the Foundation

A press is a gentle yet powerful machine. A forging hammer is a type of machine that forms things in a way similar to a press. In the case of a hammer, the reactive force generated between the dies...

shutterstock_222893611.jpg)

Considering Forming Loads When Selecting a Press

This article covers the topic of press forming loads at it relates to the selection of a press. In order to form a product that requires 1000 kN (100 tons) of pressure, it necessitates a press with...

The 3 Elements of Press Capacity "Work Capacity"

Of the 3 elements of press capacity, so far we have explained "Pressure Capacity" and "Torque Capacity," so let's now talk about "Work Capacity." Work Capacity = The Amount of Energy Work capacity ...

The 3 Elements of Press Capacity "Torque Capacity"

On the previous page we explained pressure capacity, and now we would like to talk about the next of the 3 elements of press capacity--torque capacity. What is Torque? Torque is the force used to r...

shutterstock_153596720.jpg)