Different Types of Slide Motion and Their Torque Characteristics

There are many different slide motions available for mechanical presses, and this blog post will explain the characteristics of each motion, the slide drive mechanisms that make these motions possible, and the torque characteristics that result from these different drive mechanisms.

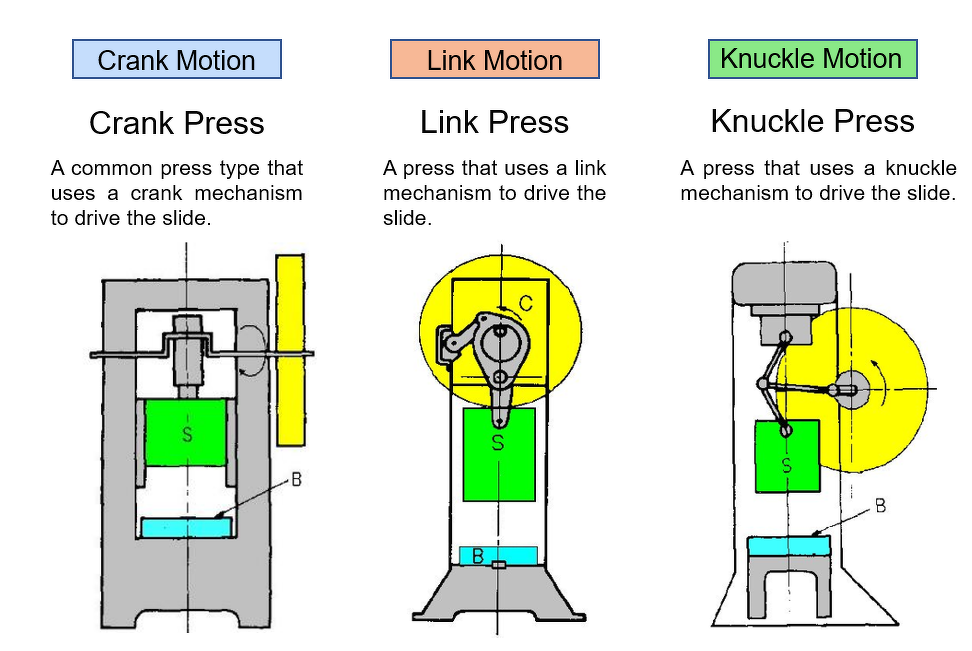

■ Representative Mechanical Press Slide Motions

We will now explain the characteristics of three representative slide motions: Crank motion, link motion, and knuckle motion.

Representative Mechanical Press Slide Motions

Let's talk about link motion and knuckle motion in somewhat greater detail.

In the case of link motion, the slide velocity in the forming portion of the stroke is 30~45% slower than crank motion when running at the same SPM as a crank motion press, and the slide velocity is fast in the non-forming portion of the stroke (i.e., its return velocity to top dead center is fast). This results in a 'soft touch' between the die and the material at the beginning of the forming portion of the stroke, which contributes to longer die life and less vibration and noise. In addition, the SPM for link motion can be set higher than the SPM for crank motion if the slide motion in the forming portion of the stroke is the same. This serves to boost productivity. However, the time allocated for the feeding or conveying of material is shorter for link motion than crank motion, and thus you may not be able to achieve the expected level of productivity from the press line as a whole.

Knuckle motion is one type of link motion, and it is a motion with a 'flat-bottomed' motion curve at bottom dead center (BDC) that enables the slide to remain in the forming portion of the stroke longer, thus making it well-suited for compression forming, such as coining and sizing. However, because it is a 'flat-bottomed' motion, it takes more time for the slide to upstroke to the position required for material feeding and conveyance, and this can be disadvantageous in terms of productivity.

■ Slide Drive Mechanisms by Motion Type

We will now show you the slide drive mechanisms that make the various slide motions possible.

Slide Drive Mechanisms by Motion Type

■ Motions (Slide Drive Mechanisms) and Torque Characteristics

Even if the press capacities and torque capacities are the same, different motions (slide drive mechanisms) result in different torque characteristics (tonnage curves). The following chart shows the torque characteristics of mechanical presses that have the same capacities and rated tonnage points.

There are no major differences between the crank motion and link motion torque characteristics. However, in the case of knuckle motion, the force capacity of the press is lower compared to the other motion types while the slide is at a high position above bottom dead center. Knuckle motion presses are suited for cold forging applications where coining or sizing is performed near bottom dead center, but they are not suited for forming at a position high above bottom dead center. Be sure to select a press with the motion best suited for the characteristics of the product being formed.