The 3 Elements of Press Capacity "Pressure Capacity"

Presses can be broadly classified as 'hydraulic presses' and 'mechanical presses, and the press type is selected based on the forming application.

When selecting a press, based on the drive mechanism characteristics it is necessary to consider the '3 Elements Of Press Capacity' defined below.

Though there are many different kinds of presses, the following explanation will use a typical crank press as an example.

What is a 'Crank Press'?

The majority of mechanical presses have a crank mechanism (see the illustration below), and these presses are used for almost all press metalforming, including sheet forming and forging applications.

Crank Press

For example, when selecting a press or planning to form a specific part using a press, the tendency is to think that a press can do the required forming if it generates the necessary pressure force.

Unfortunately, this is not always the case.

In order to avoid such a scenario, it is necessary to verify whether the "Torque Capacity" (see ② above) as well as the "Work Capacity" (see ③ above) are sufficient for the application.

Now let's begin explaining "Pressure Capacity" (see ① above).

The pressure capacity is the maximum pressure (applied force) that can be safely generated during press metalforming, and it is also referred to as the "tonnage capacity," the "nominal capacity," and the "nominal pressure."

Perhaps you are wondering why the qualifier 'safely' is included in the above statement about the maximum pressure force that can be generated.

This is because the 'pressure capacity' does not refer to the maximum tonnage load that the press can output. Rather, it refers to the maximum tonnage load that the press is able to withstand.

Let's return to the basics and define what a press is.

As noted above, the reaction forces generated during metalforming are not released to the outside but rather are exerted on and absorbed by the press itself.

Because of this, we use the phrasing 'safely' when talking about the maximum pressure that can be generated without breaking the press.

For example, if using a press with a capacity of 3000 kN, AIDA recommends that the press be used at 70% or less of its rated pressure capacity (2100 kN or less) to assure safe, long-term utilization.

This is because during actual metalforming, factors such as 'material thickness variations,' 'material hardness variations' and 'die lubrication condition variations' can causes loads that exceed the anticipated load and could possibly result in an overload*.

Accordingly, we recommend that a press be used at no more than 70% of its pressure capacity.

*Because our presses are equipped with overload protectors, it is possible to prevent press deformation and cracking.

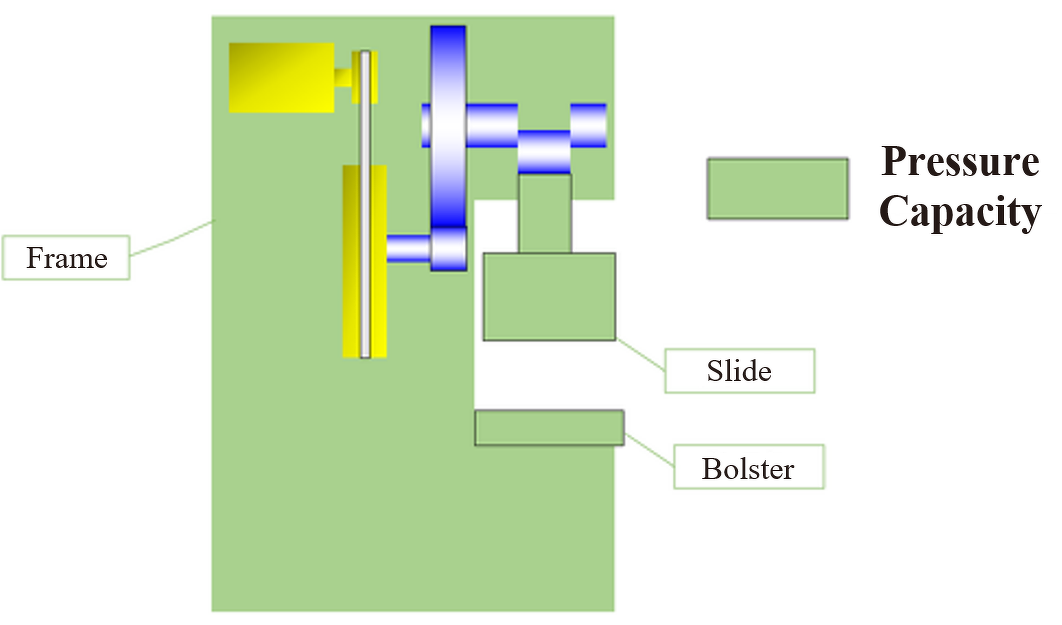

The structural components of a press that are related to pressure capacity--components that are subjected to working loads (pressure)--are shown in green in the illustration below, and include the press frame, the bolster, the slide, the connecting rod, and the crankshaft (and especially the crank pin area).

If the press is used beyond its rated pressure capacity, the green areas of the press shown in the illustration below may deform or crack.

The 3 Elements of Press Capacity: Pressure Capacity