The 3 Elements of Press Capacity "Work Capacity"

Of the 3 elements of press capacity, so far we have explained "Pressure Capacity" and "Torque Capacity," so let's now talk about "Work Capacity."

Work Capacity = The Amount of Energy

Work capacity is defined as the amount of energy that can be safely used during 1 forming stroke, and is expressed as the number of forming strokes can be safely performed in 1 minute.

Work capacity is calculated using this formula: The Applied Force x The Slide Motion Range

For example, if you look at the graph below to see the amount of work when running continuously at 60 min-1(SPM), you can see that it shows 1400Kgf・m.

Another way to state this is to say that if the pressure is 140 tons, the press can continue to push down for 10 mm.

※When expressed in SI units (the International System of Units), 1400 Kgf・m becomes 14 kJ (kilojoules).

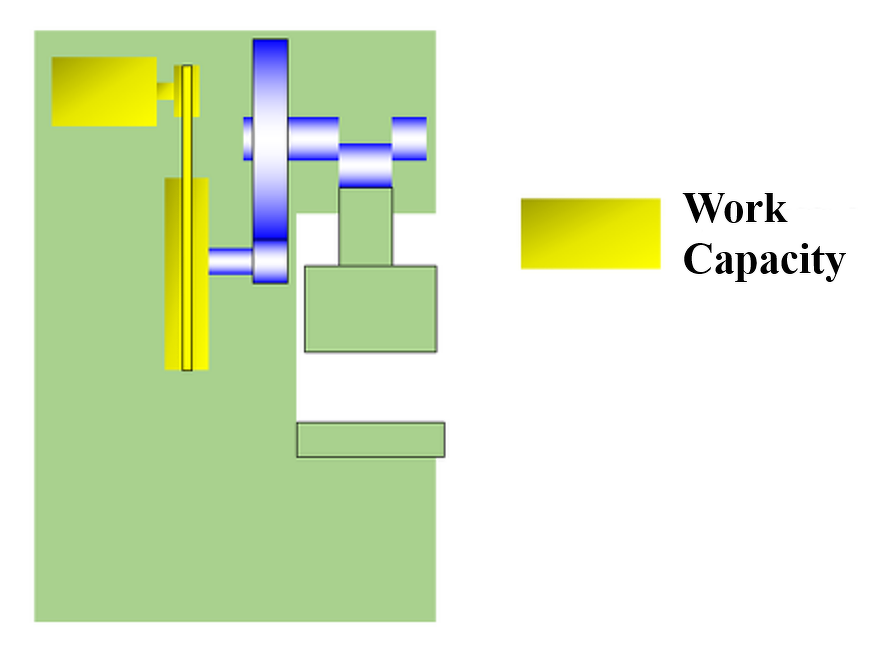

The structural areas of the press related to working capacity--the motor, flywheel, and flywheel belts, etc.--are shown in blue in the illustration below.

The 3 Elements of Press Capacity: Work Capacity

Defining Continuous Operation (Continuous Working Energy) and Intermittent Operation (Intermittent Working Energy)

A mechanical press performs work by using the stored energy (stored rotational energy) contained in the motor and flywheel.

During forming, the flywheel RPMs will slow down as energy is consumed.

Because of this, the motor tries to restore the flywheel RPM to its original speed by the time the slide has returned to top dead center.

If the flywheel RPM can be restored by the time the slid reaches top dead center, it is possible to continue forming without stopping.

This is referred to as continuous operation. (Shown to the left in the illustration below.)

On the other hand, if the flywheel RPM cannot be restored by the time the slide reaches top dead center, the press must be stopped at top dead center or at the preset stop position to wait for the RPM to be restored, and then the press restarts.

This is referred to as intermittent operation. (Shown to the right in the illustration below.)

As shown in the above illustration, the work capacity will repeatedly fluctuate during forming as follows:

① At the pre-forming position (top dead center), the stored energy is at full capacity.

② When forming starts and as the slide approaches bottom dead center, the stored energy is being consumed.

③ Once the end of the forming portion of the stroke is reached, the consumed energy will be replenished (as the slide returns to top dead center) until the next forming starts.

When the Press is Used Beyond its Work Capacity

This will cause the press SPM to begin to decrease.

If the press continues to be used in this condition, in a worst-case situation the motor in the press can overheat and burn out.