Articles relating to "Machining."

Presses form products by exerting the necessary load on material via the dies. If the load is not transmitted appropriately, it can result in defective products and cause die damage. In this ...

Draw-Forming (Part 3): How to Determine the Optimal Press Capacity

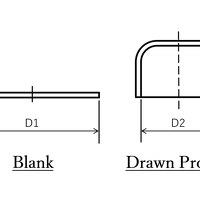

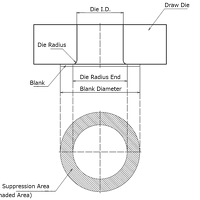

In Parts 1 and 2 of this series, we discussed the 'wrinkling suppression force' necessary to suppress wrinkling and cracking when draw-forming and how to calculate the 'appropriate number of draws....

Draw-Forming (Part 2): How Do You Calculate the Appropriate Number of Draws?

In Part 1 of this series we discussed the 'wrinkling suppression force' necessary to suppress wrinkling and cracking when draw-forming. Draw-forming is a methodology that can produce seamless, beau...

Draw-Forming (Part 1): How Do You Calculate the Optimal Wrinkling Suppression Force?

In this 3-part series we will be discussing 'draw-forming.' Drawforming is a methodology that can produce seamless, beautifully formed products, but it is very important to do calculations beforeha...

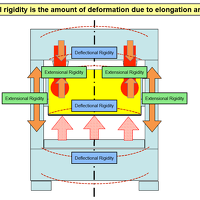

What is Press Rigidity?

When defects are found in press-formed products and other issues such as noise and vibration occur, you have perhaps heard someone comment, 'I don't think this press is rigid.' There are also diffe...

Allowable Off-Center Load Diagrams--Part ②

In our previous blog post titled "Allowable Off-Center Load Diagrams--Part ①," we talked about cases where the load center is some distance from the center of the press (i.e., there is off-center l...